Adopt a Robust Quality Management System with PPAP in Odoo ERP

- July 2, 2024

- Posted by: tony

- Categories: Blog, Odoo, PPAP

Are you currently using Excel spreadsheets, word docs, and similar tools to manage quality in your business? While these tools are useful, they often fall short in handling the complexities of quality assurance in manufacturing. The Production Part Approval Process (PPAP) offers a comprehensive solution, especially when dealing with the intricacies of large-scale production and supplier management. PPAP is a risk classification and qualification process used to determine whether a production run will produce parts with consistency and repeatability, both internally and with suppliers.

New to Production Part Approval Process (PPAP)? Here’s what it is

The Production Part Approval Process (PPAP) is a standardized procedure utilized primarily in the automotive and manufacturing industries. Its main goal is to ensure that the production process consistently produces parts that meet customer specifications and quality requirements. PPAP is part of the Advanced Product Quality Planning (APQP) framework and adheres to standards set by the Automotive Industry Action Group (AIAG).

The objectives of PPAP are threefold: to verify supplier capability, to document the production process, and to establish confidence. Verifying supplier capability ensures that the supplier’s production process can consistently produce parts that meet the customer’s specifications during actual production runs. Detailed documentation of the production process, including materials, design, and quality control measures, is also essential. This thorough documentation builds confidence in the supplier’s ability to meet production demands and maintain high-quality standards.

Implementing the Production Part Approval Process (PPAP) within an Odoo ERP system can streamline your quality management and ensure that all production processes meet stringent industry standards. Odoo, with its modular architecture and customization capabilities, provides an excellent platform for integrating PPAP, thus enhancing overall production efficiency and product quality.

Industries Benefiting from PPAP — Automotive, Electronics, Medical Devices, Consumer Goods, and others

PPAP is beneficial in industries where consistent quality and adherence to specifications are critical. It ensures that components and systems meet stringent standards in sectors like automotive, aerospace, medical devices, electronics, consumer goods, heavy equipment, and household appliances. By verifying that parts meet exacting standards, PPAP maintains product quality, regulatory compliance, and customer satisfaction across various industries.

Key Elements of PPAP

PPAP consists of several key elements that collectively ensure a thorough assessment of the production process. These elements include:

- Design Records: Detailed drawings and specifications of the part, including revisions.

- Engineering Change Documents: Document changes made to the design after the initial release.

- Customer Engineering Approval: Proof of customer engineering approval when required.

- Design Failure Mode and Effects Analysis (DFMEA): Analysis of potential failure modes in the design phase and their effects.

- Process Flow Diagram: Visual representation of the manufacturing process steps.

- Process Failure Mode and Effects Analysis (PFMEA): Analysis of potential failure modes in the manufacturing process and their effects.

- Control Plan: Detailed plan outlining how the production process will be controlled to ensure quality.

- Measurement System Analysis (MSA): Assessment of the measurement systems used to ensure their accuracy and reliability.

- Dimensional Results: Measurements of the part to ensure it meets design specifications.

- Records of Material/Performance Tests: Results of tests to ensure materials and performance meet specifications.

- Initial Process Studies: Data from initial production runs to demonstrate process capability.

- Qualified Laboratory Documentation: Evidence that testing has been performed by a qualified lab.

- Appearance Approval Report (AAR): Documentation for parts with appearance requirements.

- Sample Product: Actual sample parts produced during the PPAP run.

- Master Sample: A sample part retained as a reference for future production.

- Checking Aids: Tools or fixtures used to inspect parts.

- Customer-Specific Requirements: Any additional requirements specified by the customer.

- Part Submission Warrant (PSW): Formal declaration that the part meets all customer requirements.

PPAP is crucial for ensuring that production processes are capable of consistently producing high-quality parts. It helps suppliers and customers by providing a clear framework for communication and documentation, thereby reducing the risk of defects and ensuring compliance with all quality standards.

When is PPAP Implemented?

The Production Part Approval Process (PPAP) is implemented in several situations:

- New Part Introduction: When a new part or product is introduced into production.

- Engineering Changes: When there are engineering changes to design records, specifications, or materials of an existing part.

- New or Modified Tools: When new tooling, fixtures, or significant changes to existing tooling may affect the part’s fit, form, or function.

- New Supplier: When a new supplier is being vetted to produce an existing part, or when an existing supplier moves production to a new location.

- Process Change: When there are changes to the manufacturing process, such as changes in the sequence of operations, new or modified equipment, or significant changes in production methods.

- Material Change: When there is a change in the raw materials or any components of the materials used in the part production.

- Production Location Change: When production moves to a new facility or different geographic location.

- Production Volume Change: When there is a significant increase or decrease in the production volume that may affect process capability or quality.

- Correction of Discrepancies: When correcting discrepancies found during previous PPAP submissions or quality audits that may affect the part.

- Customer Request: When the customer specifically requests a PPAP submission due to quality concerns, regulatory requirements, or other reasons.

- Out-of-Specification: When parts have been produced out of specification and corrective actions have been implemented, necessitating re-validation of the production process.

- Supplier Quality Concerns: When there are recurring quality issues or significant quality concerns raised about the parts supplied by a supplier, requiring re-validation.

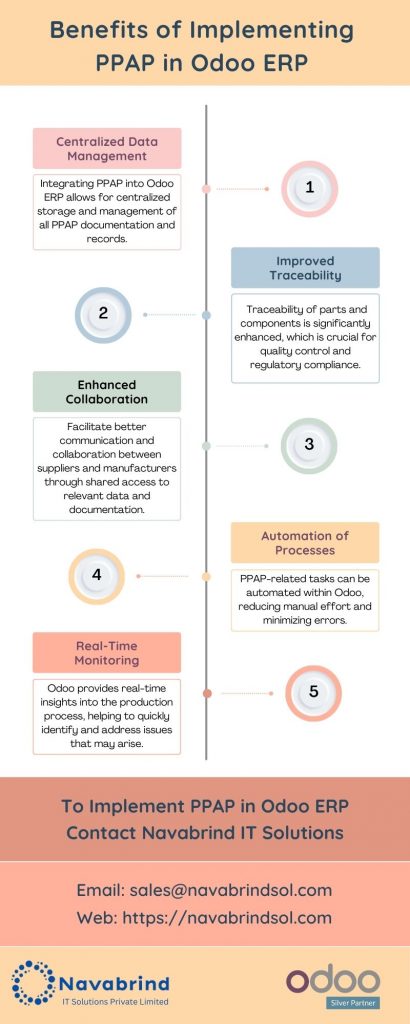

Benefits of Implementing PPAP in Odoo ERP

- Centralized Data Management: Integrating PPAP into Odoo ERP allows for centralized storage and management of all PPAP documentation and records.

- Improved Traceability: With all data located in a single system, the traceability of parts and components is significantly enhanced, which is crucial for quality control and regulatory compliance.

- Enhanced Collaboration: Odoo ERP facilitates better communication and collaboration between suppliers and manufacturers through shared access to relevant data and documentation.

- Automation of Processes: Many PPAP-related tasks can be automated within Odoo, reducing manual effort and minimizing errors.

- Real-Time Monitoring: Odoo provides real-time insights into the production process. It also helps to quickly identify and address issues that may arise.

Key Steps to Implement PPAP in Odoo ERP

1. Define PPAP Requirements: Define the PPAP requirements specific to your industry and organization. These typically include design records, engineering change documents, DFMEA, PFMEA, control plans, and more. Ensure that all necessary elements are identified and documented.

2. Customize Odoo Modules: Odoo’s flexibility allows you to customize existing modules or develop new ones to meet PPAP requirements. Key modules to consider customizing include:

- Documents: For managing and storing all PPAP documentation.

- Quality: For tracking quality checks, control plans, and non-conformances.

- Manufacturing: For integrating process flow diagrams and production controls.

- Project: For managing PPAP submissions and approvals as projects.

3. Develop Custom Workflows: Develop custom workflows within Odoo to manage the PPAP process. This includes workflows for document approval, change management, and quality checks. Ensure that workflows align with your PPAP requirements and facilitate seamless process management.

4. Integrate with Existing Systems: Ensure the PPAP implementation integrates smoothly with existing systems such as supply chain management, inventory control, and customer relationship management (CRM). Odoo’s modular structure and extensive API support can facilitate these integrations.

5. Train Your Team: Provide comprehensive training for your team on using the PPAP functionalities within Odoo. This includes training on how to enter and manage PPAP data, how to use customized workflows, and how to generate necessary reports.

6. Test the Implementation: Conduct thorough testing of your PPAP implementation within Odoo. This involves running pilot projects to identify issues or gaps in the process. Use the insights gained from testing to refine and optimize the system.

7. Go Live and Monitor: Once testing is complete, move to the live implementation of PPAP in Odoo. Monitor the system closely during the initial phase to ensure everything functions as expected. Be prepared to make adjustments based on real-world usage and feedback.

Example Workflow for PPAP in Odoo

1. Design Records and Engineering Changes

- Upload and manage design records and engineering change documents in the Odoo Documents module.

- Use version control to track changes and ensure that the latest documents are always available.

2. DFMEA and PFMEA

- Document Design Failure Mode and Effects Analysis (DFMEA) and Process Failure Mode and Effects Analysis (PFMEA) in the Quality module.

- Link these analyses to specific products and manufacturing processes.

3. Control Plans and Measurement System Analysis (MSA)

- Create and manage control plans within the Quality module.

- Conduct and document Measurement System Analysis (MSA) to ensure measurement systems are accurate and reliable.

4. Dimensional Results and Material Tests

- Record dimensional results and material/performance tests in the Manufacturing and Quality modules.

- Use custom fields and forms to capture all relevant data.

5. Initial Process Studies and Qualified Laboratory Documentation

- Document initial process studies and qualified laboratory documentation in the Quality module.

- Ensure all data is linked to the respective part and accessible for review.

6. Part Submission Warrant (PSW)

- Generate and manage Part Submission Warrants (PSW) in Odoo.

- Use the Project module to track the submission and approval process, ensuring all stakeholders are involved.

Identifying a Technology Partner for PPAP Implementation

Identifying a technology partner capable of implementing the Production Part Approval Process (PPAP) for an e-commerce company involves several critical steps. Firstly, look for a partner with a proven track record in the e-commerce sector, demonstrating experience in quality assurance and process optimization. The ideal partner should have a deep understanding of PPAP principles and how they can be adapted to the e-commerce environment, where rapid product cycles and high customer expectations are prevalent.

Evaluate their expertise in integrating PPAP with existing systems such as supply chain management, inventory control, and customer relationship management (CRM) platforms. Additionally, assess their ability to provide comprehensive training and support to ensure your team can effectively manage the PPAP process. Strong references and case studies from previous clients in similar industries will also indicate their capability. Finally, consider their technological infrastructure and ability to scale, ensuring they can handle your company’s growth and evolving needs. By focusing on these factors, you can identify a technology partner who not only understands the nuances of PPAP but also aligns with your business objectives and operational demands.

Conclusion

Implementing the Production Part Approval Process (PPAP) within Odoo ERP can significantly enhance quality management systems and ensure consistent production of high-quality parts that meet customer specifications. By leveraging Odoo’s modular capabilities and customization options, businesses can create tailored solutions that facilitate better collaboration, improve traceability, and streamline processes. This integration not only helps maintain product quality but also ensures compliance with industry standards, ultimately leading to greater customer satisfaction and business success.

If you seek a technology partner to streamline your PPAP implementation, reach out to Navabrind IT Solutions. With over a decade of expertise in implementing Odoo ERP and digital commerce applications, we possess the deep insights needed to meet your unique requirements. Our extensive experiences ensure we are able to deliver tailored solutions that are customized, deployed and maintained to empower your business to achieve superior quality management and operational efficiency. Email us at sales@navabrindsol.com to schedule a demo.

Schedule a conversation with us now!

Related Articles

-

Best Practices for Implementing and Managing Adobe Experience Manager

Best Practices for Implementing and Managing Adobe Experience Manager July 16, 2024 Posted by: tony Categories: Adobe Experience Manager, Blog No Comments Adobe Experience Manager (AEM) is a powerful content management platform that integrates digital asset management, site management, and content delivery to enhance customer experiences across various channels. Successful AEM implementation involves clear objectiveJuly 16, 2024 Read more -

How Does Adobe Experience Manager (AEM) Integrate with E-Commerce Platforms

How Does Adobe Experience Manager (AEM) Integrate with E-Commerce Platforms July 16, 2024 Posted by: tony Category: Uncategorized No Comments In the dynamic landscape of digital marketing, the power of Adobe Experience Manager (AEM) is amplified through its seamless integration with various systems, transforming it into a powerhouse for personalized, omnichannel customer experiences. This blogJuly 16, 2024 Read more -

Top 8 Benefits of Adobe Experience Manager for the E-Commerce Industry

Top 8 Benefits of Adobe Experience Manager for the E-Commerce Industry July 15, 2024 Posted by: tony Categories: Adobe Experience Manager, Blog No Comments Adobe Experience Manager (AEM) stands out as a premier content management solution, offering a host of benefits that elevate digital experiences. It provides seamless content management with an intuitive interface, enablesJuly 15, 2024 Read more

How can we help you?

Get in touch with a solutions consultant that can share best practices and help solve specific challenges.